Description

Founded in 2006, Romas Machinery technology co, Ltd is Designated to provide our clients globally with a turn-key Smart production solution.

Automation Solution’ Smart Production’ solution Consultation, Design, and Installation Global Automation System Installation and Maintenance Services.

The Machine Main Technical Parameters

| Parameters | Contents |

| Material | Acrylic |

| Sheet thickness | 2-8mm |

| Forming length | 12000mm(Customizable) |

| Forming width | 3000mm(Customizable) |

| Max forming depth | 1000mm(Customizable) |

| Work efficiency | 2-3min/pcs |

| Heating oven | Gas/ Electricity and Oil |

| Operating gas pressure | 3kpa |

| Max gas consumption per hour | 100000 kcal is 12 m3 / h |

| Power supply | 380 V / 50 Hz / 3Ph |

| Air pressure | 0.6-0.8Mpa |

| Machine size(L×W×H) | 15000*4200*4200mm |

| Net weight | About 16000kg |

Technical Data series

| Components | Description | QTY |

| Heating oven | 1.Room size:12000*3000*1000mm;

2.Liner is 201 stainless steel plates; the outer wall is cold plate; 3.Oven wall thickness:100mm, filled with insulation foam; 4.Heating:electric heat tube, the upper and lower double-sided heating; 5.Temperature: multi-sensor automatic thermostat; 6.Temperature range: room temperature to 399 degrees; 7.Power 45KW+45KW=90KW; 8.Movable blocking door can divided the oven into two parts; |

1set |

| Forming platform | 1.The largest forming size:12000*3000mm;

2.Transmission: hydraulic; 3.Balance error:3mm; 4.Operating modes: command-style semi-automatic; 5.Transmission of plastic sheet: Directive mechanical transmission; 6.Up and down travel limit:1m; 7.Clamp method: grouping manual rapid clips; |

1 set |

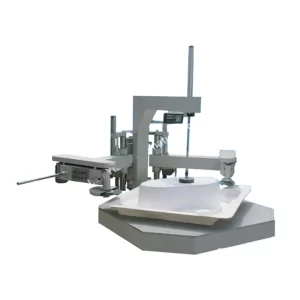

| Spa forming platform | 1.The largest forming size:3000*3000mm

2.Transmission: hydraulic; 3.Balance error:3mm; 4.Operating modes: command-style semi-automatic; 5.Transmission of plastic sheet: Directive mechanical transmission; 6.Up and down travel limit: 1m; 7.Clamp method: grouping manual rapid clips; |

1 set |

| Vacuum pump | 100 liter rotary vane vacuum pump or water ring vacuum pump | 1 set |

| Vacuum tank | 1.Volume: Recommendation 20 cubic meters, horizontal layout;

2.Maximum negative pressure: -0.9; 3.Automatic vacuum control; 4.Vacuum time:12 minutes; |

1 set |

| Hydraulic system | 1.7,5P hydraulic station:1pc

2.Safety limit load: 12 tons 3.Hydraulic rod: two pieces each elevating platform; 4.Diameter of piston rod: 80mm; 5.Hydraulic weight transfer; 6.Automatic pressure maintaining , adjustable pressure; |

1 set |

Auxiliary Equipments

Edge sawing machine

Resin Mixer

FRP Vacuum forming mold