Description

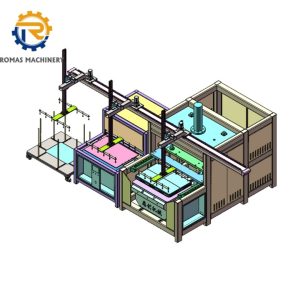

Fully Automatic Acrylic LED Lamp cover Shell Blowing Forming Machine

Production process flow of Fully automatic machine:

- After connecting the air source, check whether the pressure is stable in the range of 0.6-0.8mpa, and adjust the pre blowing and forming pressure to appropriate;

- Turn on the power and turn on the power switch. Press the “power on” button to power up the system.

- Turn on the oven for heating and set the temperature of each section according to the process requirements. The recommended temperature range is 350-500 ℃(depending on the thickness of the sheet). The heating system generally needs 10-15 minutes of heating time and 30 minutes of stabilization time; And move the tray into the oven for preheating;

- Start the oil pump and conduct a manual test run;

- Manually operate each part to confirm that the action is normal; Operate all components to reset.

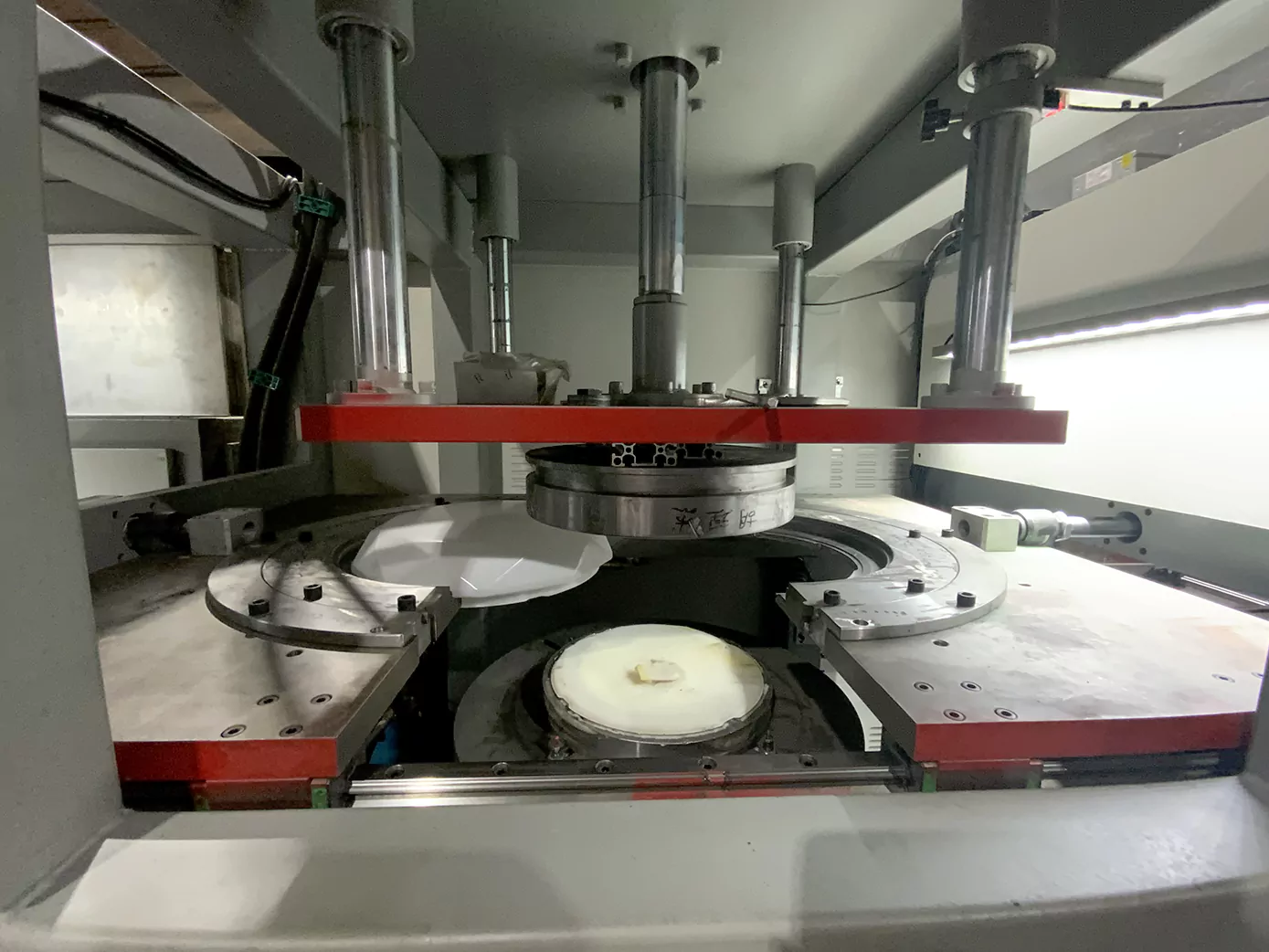

- Mold installation: fix the side mold, upper mold, and bottom mold (or knife mold) respectively; Clean and degrease the mold; Lay about 5mm sponge on the bottom mold (or knife mold);

- Place the cleaned sheets on the rack, with a maximum stack of 300 sheets. Make three sides of the sheet close to the equipment;

- Adjust the position of the vacuum suction cup to make it suitable for the currently used sheet;

- Determine the position of material rack, pallet a, pallet B, and host through trial transportation;

- Start automatic operation, check product quality, and adjust relevant parameters as needed;

- After ensuring the product quality is OK, the machine will produce in a full-automatic batch.

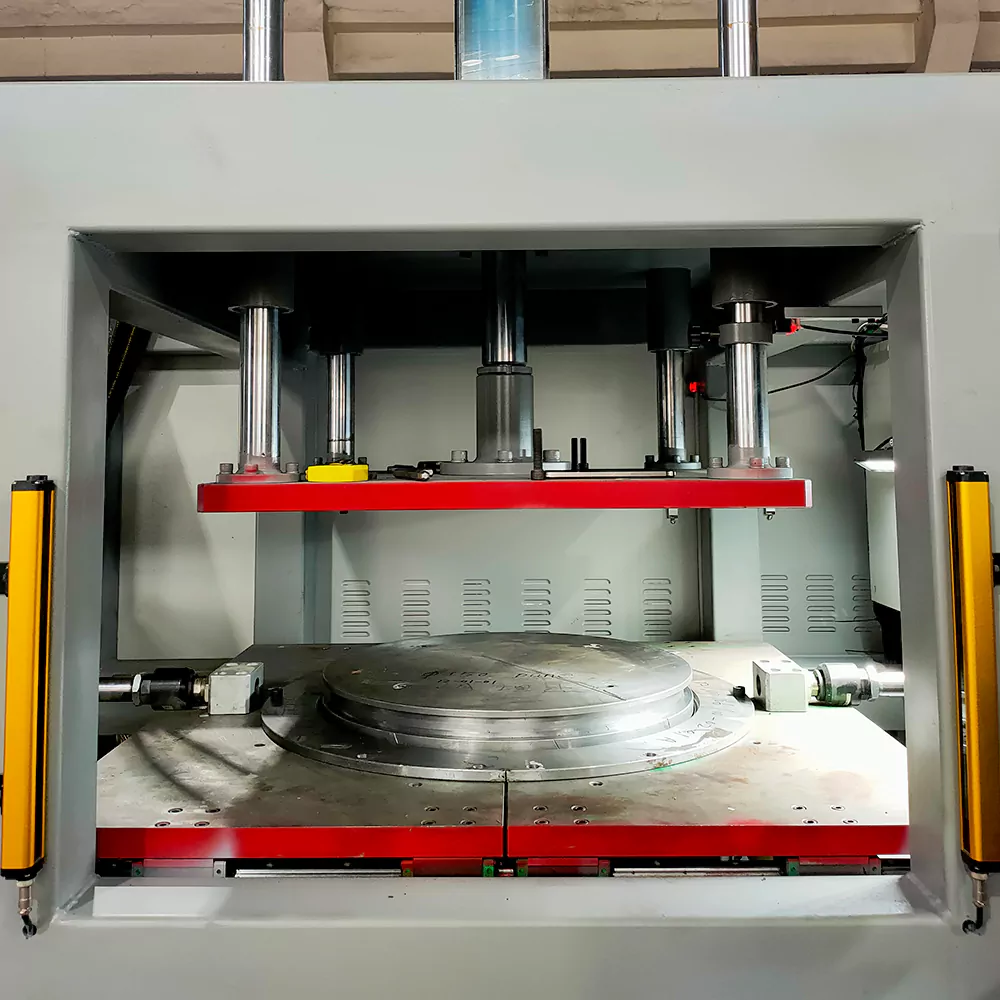

The Mold parts

The Machine Technical Specification

| Model | RASF-A800 |

| Forming Dimensions. | ≤250~800mm for the lampshade |

| Forming Height | ≤200mm |

| Forming Thickness | 1-3.5mm |

| Machine Color | As the client’s requirement or our latest update colors |

| Power supply | 380VAC/3phase/50HZ |

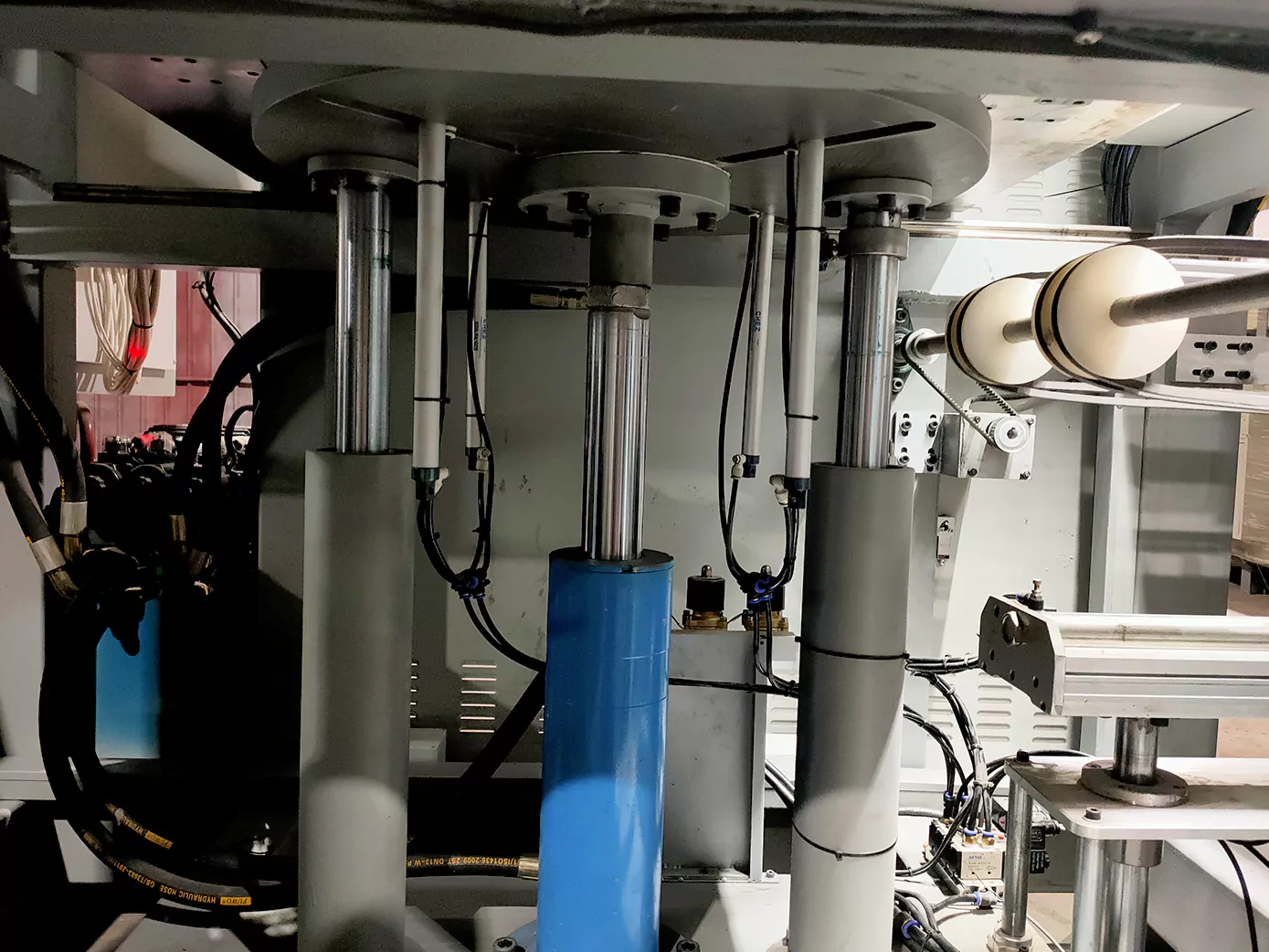

| Upper mold | Hydraulic pressure + Hinge |

| Air pressure | 0.5-0.8Mpa |

| Suggest air compressor | 10~15HP |

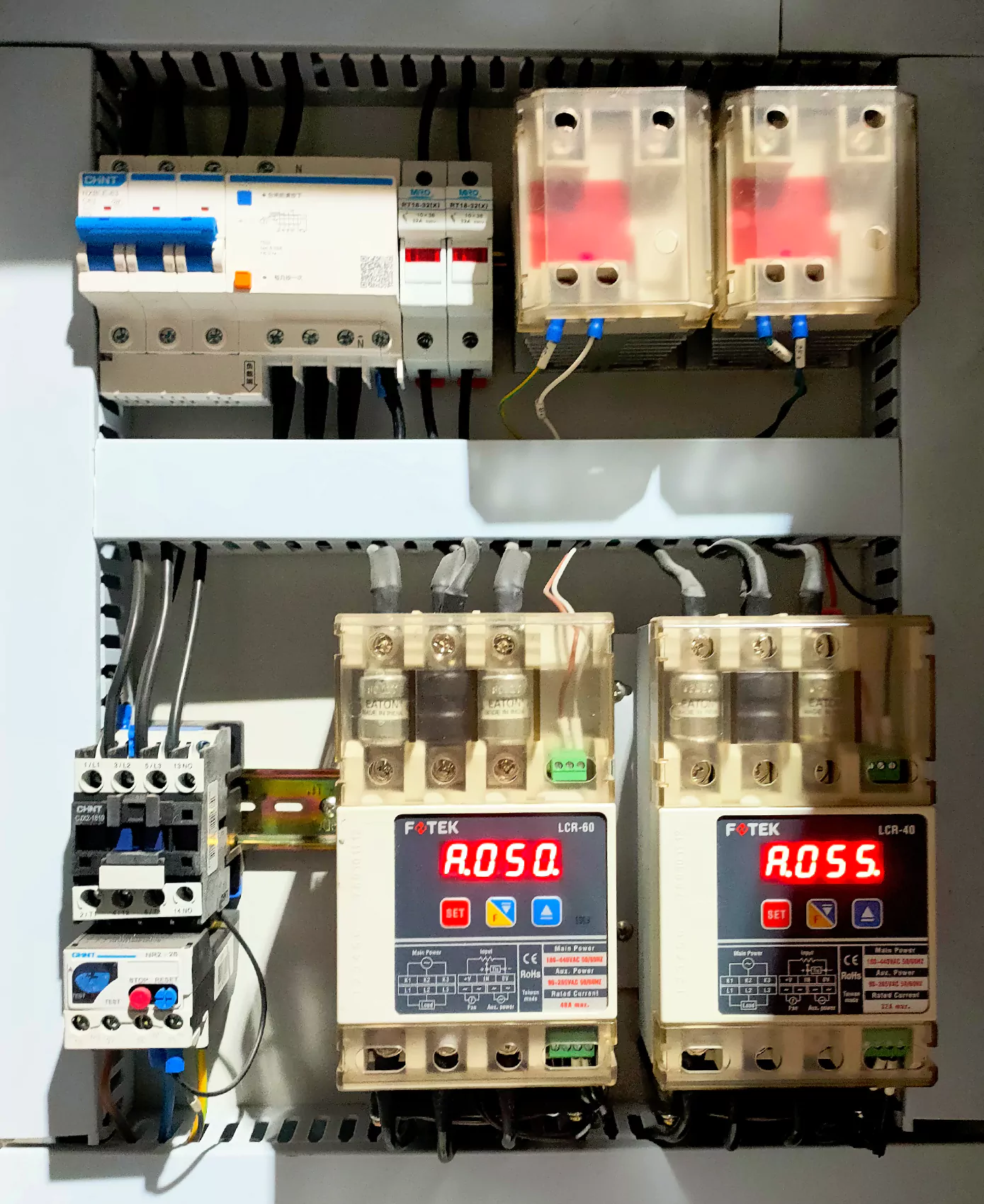

| PLC | “Mitsubishi” Japan |

| Touch screen | “WeinView” Taiwan |

| Safety device | Safety curtain |

| Material moving | Servo motor |

| Switch | “DELIXI” or “CHNT” China |

| Air Cylinder | “Zhicheng” China or “Airtac” Taiwan |

| Electromagnetic Valve | “Airtac” Taiwan |

| Consumption | 30KW |

| Machine size(L×W×H) | 3500*1600*2200mm |

| Machine weight | About 1500~2500KG |

The samples show

The Machine parts show

The purpose of realizing production process control automation is to ensure product quality, reduce consumption, simplify operation, improve automatic production and effectively improve output.

Loading container

The machine could be loaded into the 20GP or 40HQ container, the transportation cost is not high it’s also easy and convenient to install the machine in your factory!