The plastic products that we use in our daily life are prepared through a vacuum forming process. It is a process in which a vacuum forming machine is used to shape the plastic material. The bottles, cans, buckets, and other complex plastic material is prepared through this process. It is a very famous technique across the world, but getting it right requires particular expertise that very few factories have. At Roma Machinery, we have specialized in vacuum forming and other related machines for many years.

In this article, we will discuss the significant steps that are involved in the procedure of vacuum forming. Read on to know what these are:

Preparation of the mold:

The first step is the formation of the mold. A mold is constructed in the shape that the plastic will form around. This mold can be in a variety of different materials, including wood, MDF, or polystyrene. Often where possible, the mold should have angled edges. This will allow the product to pop out of the plastic when the vacuum forming is finished.

Placing the vacuum in vacuum former:

Once made, the mold is placed into the vacuum former. A plastic sheet should then be clamped above, but not on, the mold.

Place the heater above the plastic:

The heater in the vacuum former should then be positioned above the plastic. This will eventually heat up, warming the plastic and ensuring that it is perfectly flexible and mouldable.

Move the shelf toward plastic:

After a few minutes, the plastic should be at the correct temperature to allow molding. Once this is the case, the shelf on which the mold is positioned should be moved upwards and into the plastic. You can use a handle to do this.

Switch the vacuum former on:

The vacuum former will then be switched on, which removes all air from the machine. This will allow the plastic to form the shape of the mold.

Remove the sheet from the vacuum former:

Once it has cooled, remove the plastic sheet from the vacuum former. Remove the mold from the machine and then trim any excess or unwanted plastic from the formed sheet.

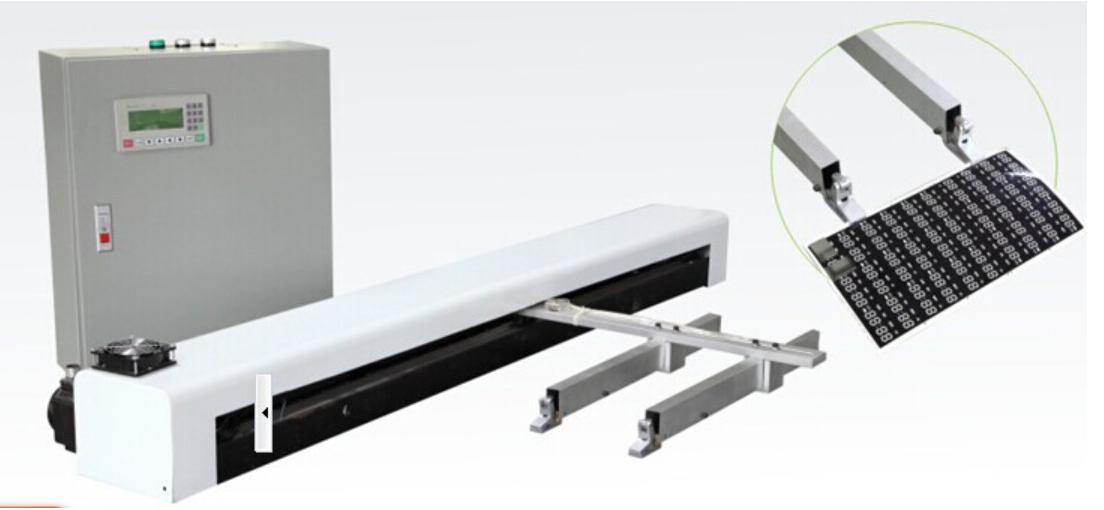

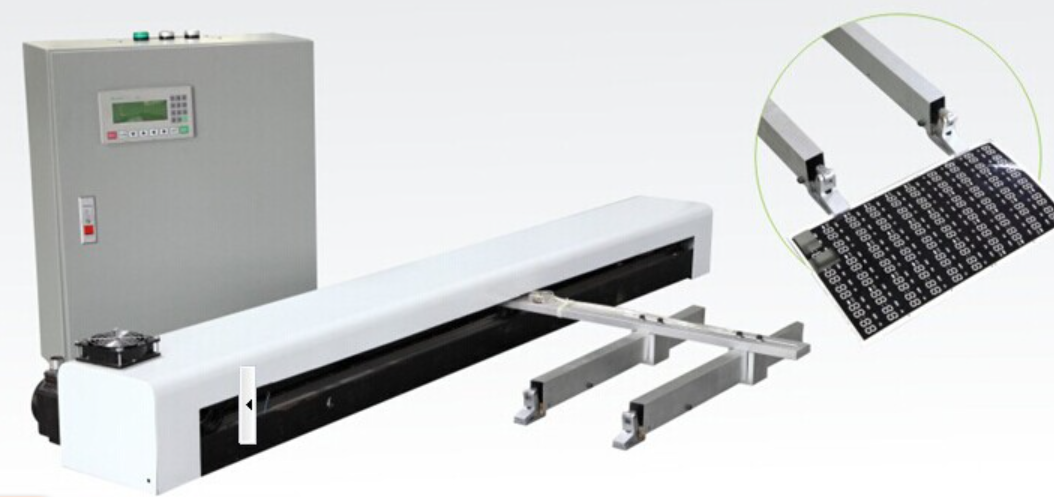

Vacuum forming machine supplier:

Among various companies, Romas Machinery is the leading manufacturer and supplier of a wide variety of automated products. Visit our official website to learn more about our products, and visit or contact us to get a quote.