Description

Product Description

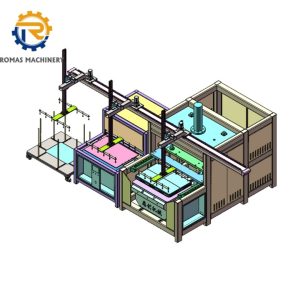

This machine is based on infrared radiation heating, positive pressure blow up molding equipment, and through the specialized design, elaborate, make you simple operation, easy to use which is a simple chimney or light box production equipment. There are two parts of one set machine, one part is for material heating, another part is for products forming.

1st. Feature

- This machine is based on infrared radiation heating, positive pressure blow up molding equipment, and through the specialized design, elaborate, make you simple operation, easy to use which is a simple chimney or light box production equipment.

- This product use Taiwan “Airtac” original pneumatic components, electric appliance also adopt Taiwan “CKC” or “Japanese” OMRON / or PLC + touch screen, etc.

- Heating system adopts porcelain infrared heating brick + division temperature control, Temperature control will more accurate.

2nd.LSF configuration, technical parameters and operation method

The whole equipment is divided into two parts: heating units and molding machine.

The machine data of forming part

| Model | RMS–300~900 |

| Forming Dia. | ≤250~900mm for the lampshade |

| Forming height | ≤150mm |

| Forming Thickness | 1–3.5mm |

| Color | As the client’s requirement |

| Power supply | 380VAC/3phase/50HZ |

| Upper mold | Hydraulic pressure + Hinge |

| Air pressure | 0.5-0.8Mpa |

| Suggest air compressor | 10~15HP |

| PLC and Touch screen | “Mitsubishi” Japan |

| Touch screen | “WeinView” Taiwan |

| Safety device | Safety curtain |

| Switch | “DELIXI“ or “CHNT“ China |

| Air Cylinder | “Zhicheng” China or “Airtac” Taiwan |

| Electromagnetic Valve | “Airtac” Taiwan |

| Consumption | 100W |

| Machine size(L×W×H) | 2000*1300*2100mm |

| Machine weight | 1500KG |

Heating units:

- Oven installation

1, Oven of heating power is about 54Kw, three-phase four-wire type, making the fuselage grounded. Suggest input cable not less than 16mm2, or carrying capacity is greater than 80A

2, Oven need to put on the smooth and solid ground, the installation environment request ventilated, dry, far from flammable objects. Avoid install in more dust, moisture, vibration environment.

Adopting automatic turn disc heating mode of sheet heat, make sheet of each place can be heated evenly.

Using zoning temperature control and closed heating (set inside and outside temperature area), make the hot furnace temperature and display temperature of temperature difference is smaller.

Tray and box door lifting to better use of heat energy to better utilize heat energy, improve efficiency

Thermal relay: “Shilin”

- The main component:

Temperature control meter: “Yangming”

Fever brick: ceramic infrared heating brick

Disc: aluminum alloy + upper berth high-temperature blanket

Disc size: φ1000mm

Machinery size: L2240×W2240×H1330mm

Forming units (common molding crew)

The pressure can use pneumatic or hydraulic, is depend on customer’s requirement.

- The equipment single-phase 220V power supply, suggest use 2.5 mm2 cable wiring, airframe to grounding.

- The equipment adopts pneumatic drive, gas supply pressure 0.6-0.8 Mpa, flow do not less than 1m3 / min, clean, dry air pressure required small ripple.

- The machine need to put on the smooth and solid ground, the installation environment request ventilated, dry, far from flammable objects. Avoid install in more dust, moisture, vibration environment.

The main component:

PLC: “MITSUISHI” Japan;

Machinery size: L2000×W1300×H2100mm

The machine data of heating part

| Model | RMA–300~900H |

| Forming Thickness | 1–3.5mm |

| Color | Same with forming part |

| Power supply | 380VAC/3phase/50HZ |

| Relay | “ Schneider “ |

| Temperature controller | SKG |

| Infrared ceramic heater | China |

| Consumption | 22KW |

| Machine size(L×W×H) | 2240*1120*1330mm |

| Machine weight | 800KG |

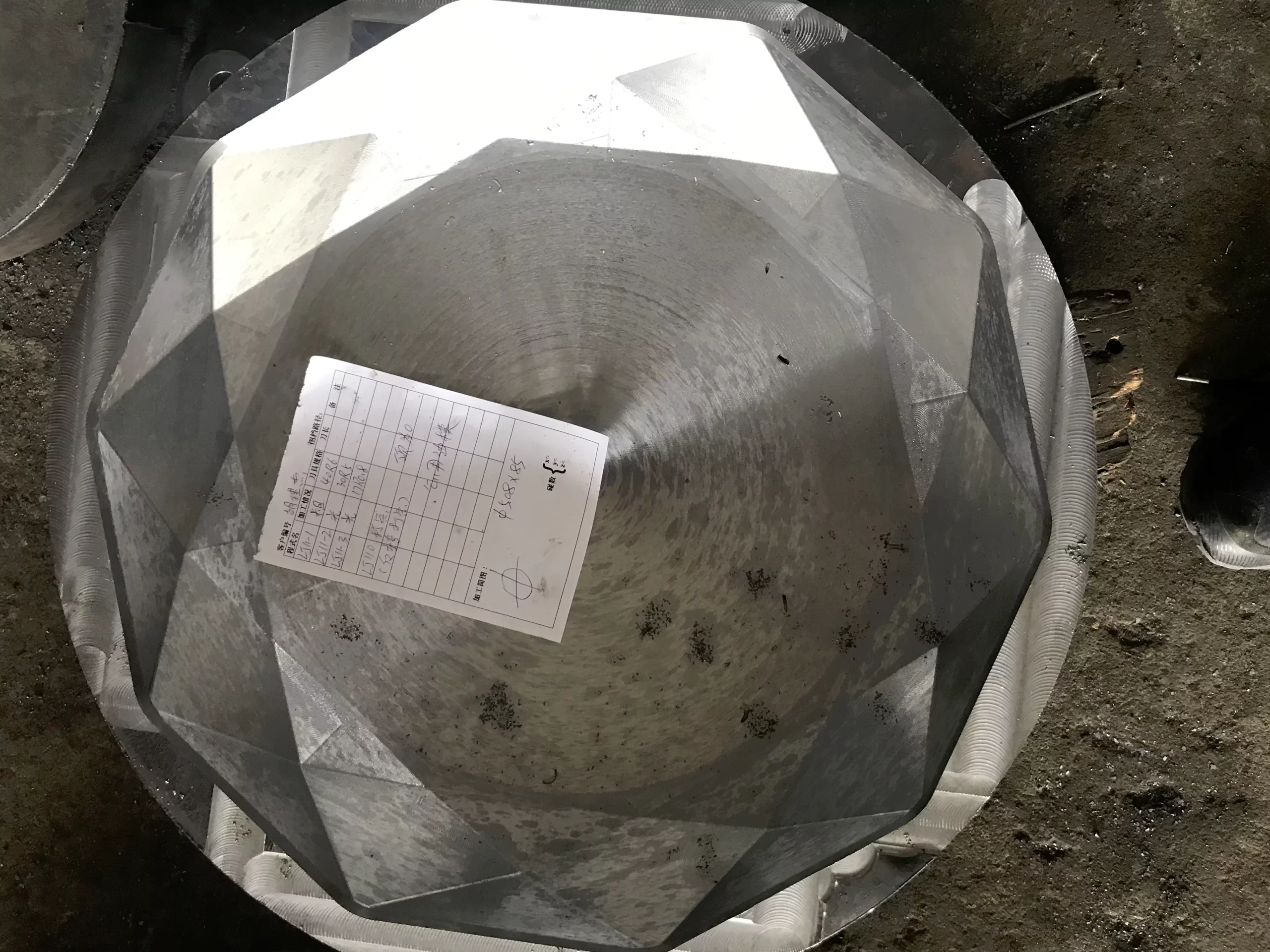

The mold

Remarks: we can offer the video of this machine. Please send the inquiry to us. We will reply you in 24hours.